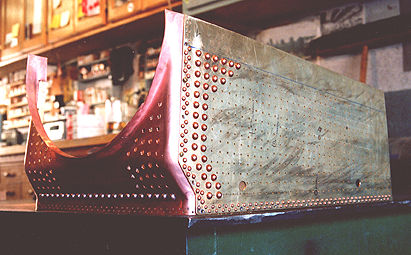

Fire Box Wrapper

Here is the fire box wrapper in progress. The throat sheet portion

was formed up from 1/16" copper. When annealed, copper is

very soft and can be worked over the MDF (medium density fiberboard)

form. The side sheets are 1/16" brass and still need to

have the 3/32" pop rivets installed to simulate hollow stays.

On most model locomotives, #4-40 acorn nuts are used to simulate

threaded flexible stay bolt caps but the Nickel Plate Berkshires

had welded flexible stay bolt caps. To simulate these, 3/16"

copper rivets were used.

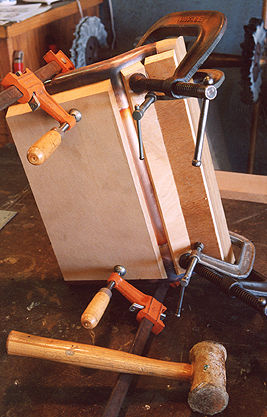

Back Head Wrapper

A back head wrapper gives a finished appearance to any locomotive.

Making a backhead wrapper is pretty simple. And this photo explains

it better than words.

Berk Throat Sheet

Forming the fire box throat sheet wrapper. This is made of .062"

copper.

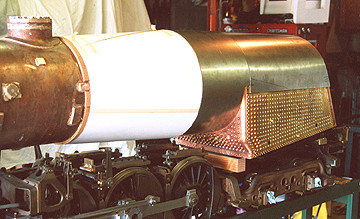

Fitting the Boiler Jacket

Fitting the boiler jacket is always a fiddle. Get some large

sheets of poster board and cut and trim them till they fit. The

nice thing about paper patterns is if you cut too much off, you

can put it back with some masking tape. When the paper patterns

fit just right, use them to mark out the sheet metal that will

be used.

Completed boiler jacket.

{BACK}

copyright

© 2004-2006, Jack Bodenmann, all rights reserved.