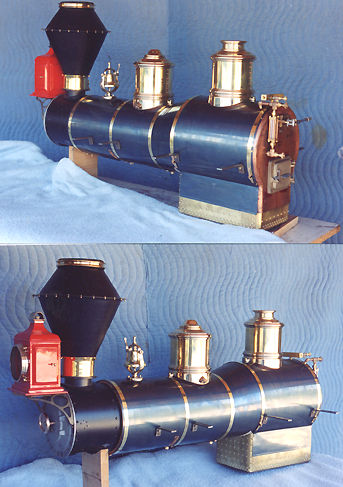

Americans:

"#40 Cow Catcher"

On a modern engine we use

the term "Pilot", but this is a COW CATCHER! Nice red

and black automotive paint and gold plated brass! Gold plating

is pretty inexpensive if you polish all the parts yourself and

then mount them on brass strips so the platers don't have to

handle them. This also prevents tiny parts from getting lost.

I usually fabricate cow catchers from hardwood, but MR. Gilday

had this nice casting from Railroad Supply.

"Domes"

These dome castings were

very nice but still needed some cleaning up. The first thing

was to cut off the mounting lugs and sand outlets. Then they

could be chucked up in the lathe and turned and polished. After

all the turning and polishing was done the mounting lugs and

sand outlets were silver soldered back on. Then just a light

buff on a cloth wheel and you can see the results. All the polished

brass was gold plated on this engine, that way you could run

it all day long and the brass wouldn't tarnish. Something to

consider on an engine with this much brightwork.

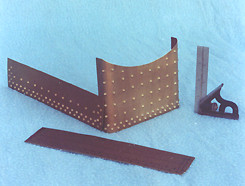

"Fitting Backhead Wrapper"

Here we are fitting the

boiler jacket to the backhead wrapper. Make sure to allow for

the thickness of the insulation under the backhead wrapper and

use little #1-72 or #0-80 screws to join them. When fitting the

boiler jacket to the backhead wrapper put a couple layers of

masking tape between them to allow for the thickness of the paint,

or you will tear you hair out later trying to get the holes to

line up!

"American" photo "Forming Backhead wrapper"

A backhead wrapper is something

that will add to the appearance of a loco and perhaps also the

performance, as you can put some insulation under it. This wrapper

was made of .032" copper. I now make them from .062"

copper as it doesn't wrinkle so easily. Make a form out of particle

board or MDF (medium density fiberboard). Hold it in place on

the form with a piece of 1/4" plywood and some "C"

clamps. Then start working the edges over the form with a rawhide

mallet. Don't use a metal hammer or you will put dents in the

copper! You will have to remove the copper from the form and

anneal it a several times by heating it to dull red and quenching

it in cold water. The colder the water the better, I use ice

water.

Here is the firebox wrapper for #40.

A firebox wrapper is a

fairly simple way to improve the appearance of most any steam

loco, even a narrow firebox engine, but will greatly add to the

appearance of a modern wide firebox engine. This wrapper is made

from .020" shim brass. The rivets are just embossed as there

isn't room between the frame and actual firebox for real rivets.

On a steam loco with hollow stays you can use 3/32" pop

rivets to simulate them. There just wasn't room here.

"#40 Boiler & Wrappers"

Here we have all our work

making wrappers and such starting to pay off. You can see how

the backhead wrapper trims out the boiler in the cab. And also

how the firebox wrapper gives the boiler a prototypical look,

not nearly as important on a narrow firebox tea kettle as a modern

wide firebox engine. This is one detail that really pays off!

{BACK}

{HOME} {A&C SHOPS} {BERKSHIRE} {AMERICANS} {No. 9} {CARS} {JEWELRY} {CONTACT}

copyright

© 2004, Jack Bodenmann, all rights reserved.