#9 Saddle Tank

Saddle Tank Dies

The saddle tank dies made of MDF (medium density

fiber board), and a sheet of .062" copper.

Forming the Tank Ends

Forming the saddle tank ends with the MDF die

and a rawhide mallet. The ends will need to be annealed a couple

times.

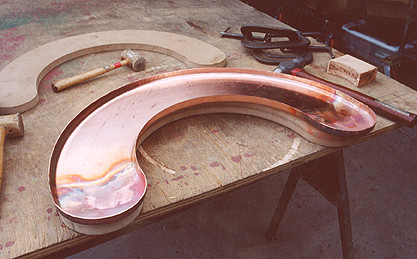

Formed Tank End

A fully formed tank end. The discoloration is

from annealing and will be cleaned up with metal prep solution.

Riveting the Tank Together

For this you need lots of Clecos, (Clecos are

the temporary spring clamps you see sticking out) lots of rivets,

and fairly long arms. Riveting is one of those jobs that is fairly

brainless, but you have to pay close attention to each rivet.

Because if the air riveter slips off the rivet head, it will

go hammering merrily off across your work piece, probably ruining

it. If this happens it's time to start over! This can be a real

hair raiser if it happens to something you have several days

or weeks work tied up in. So you learn to pay close attention

to each and every pesky little rivet.

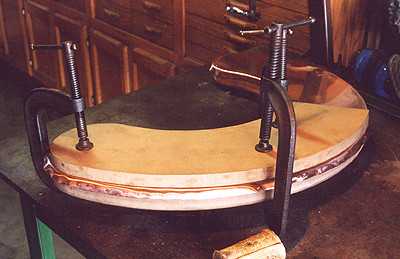

Tank Outer Shell

The saddle tank outer shell, rolled and in the

process of being drilled and fitted to the ends. There's one

more piece to be rolled for the bottom, and then the tunnel for

the steam dome must be made and fitted.

{BACK}

{A&C SHOPS} {BERKSHIRE} {AMERICANS} {No. 9} {CARS} {JEWELRY} {CONTACT}

copyright

© 2004-2006, Jack Bodenmann, all rights reserved.